Exytron: the world’s first ‘power-to-gas’ system with integrated CO2 collection and reuse

Most of the new power to gas systems turn excess electricity into hydrogen and then methane (natural gas). The methane is burnt. This generates CO2, which is vented to the atmosphere.

Exytron, of Rostock, Germany, has gone one vital stage further. It recirculates the CO2 from methane combustion in a closed loop. If this technology proves to be robust and becomes inexpensive, it solves many of the world’s remaining energy storage problems while offering zero emissions heat and power.

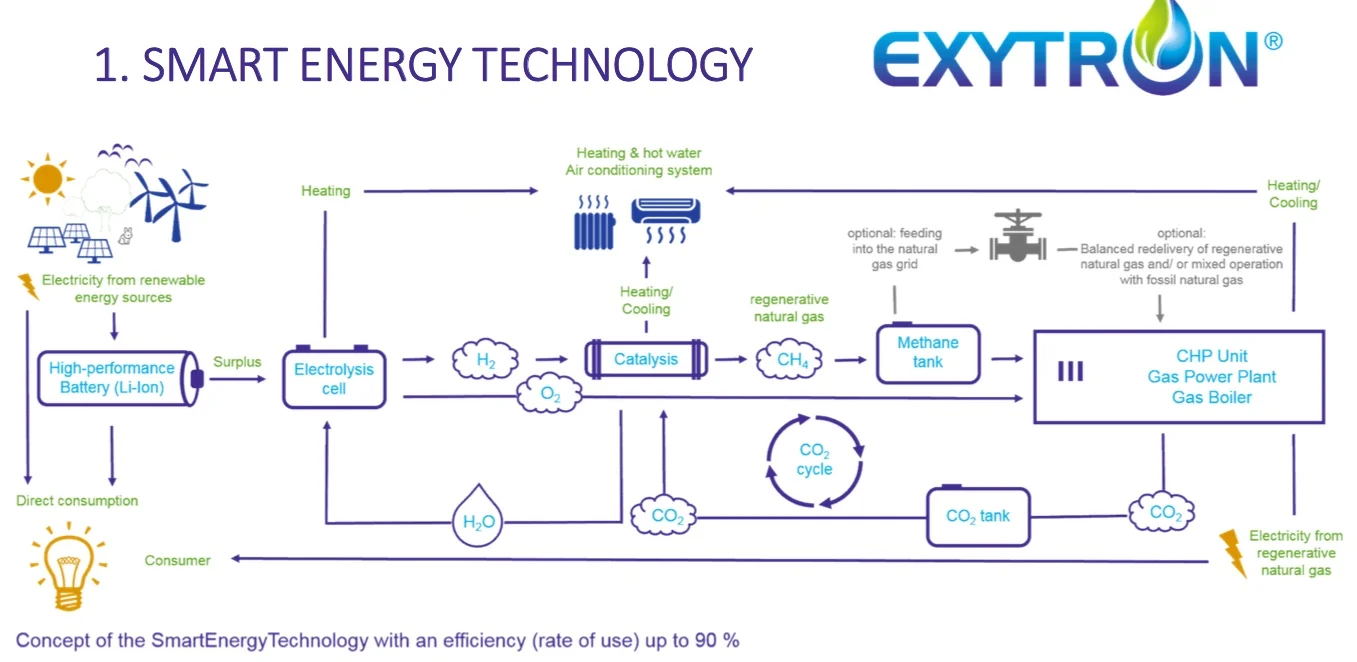

· Exytron uses surplus electricity from renewable sources to generate hydrogen and oxygen in an electrolyser.

· The H2 is fed into a reactor alongside a stream of CO2 to make methane. The methane is kept in a tank.

· The oxygen is also stored.

· When electricity or heat is required, Exytron’s machines then burns the methane in an oxygen-only atmosphere. A turbine makes electricity from this combustion.

· Heat is an important by-product. This can be used both for hot water and for space heating.

· The only products of this combustion are water and CO2.

· The water is condensed and used for future electrolysis.

· The CO2 is recirculated and used for the methane manufacture. The surplus heat generated in the process of methane generation, and then combustion, is used for water and space heating.

The unit can provide power and heat on demand. It is complemented by sophisticated computer intelligence that forecasts future electricity production from PV and the needs for power and heat.

This is the first fully closed ‘power to gas’ system in the world. It emits no CO2 to the atmosphere.

The key advances Exytron has made are

a) the use of oxygen, rather than air, in the methane combustion, meaning that the system produces a stream of very pure CO2 for reuse in the methanisation circuit. Previous attempts to do this have failed because methane will burn at an excessively high temperature in a stream of pure oxygen. Using a simple innovation, Exytron has solved this problem.

b) the methane creation process (using the conventional and well understood Sabatier reaction) employs a new catalyst.

c) All the individual processes are carried out at temperatures and pressures that can be easily, safely and cheaply achieved.

More on the technology

I visited Exyton to talk to the engineers as they prepare to install their first commercial system in a large apartment building in Augsburg, southern Germany.[1] The owners of the building are seeking to meet the German government’s targets for emissions reductions from domestic heating. The apartment block was built in the 1970s and would be very expensive to insulate to meet Germany’s 2030 standards. So the Augsburg housing company that owns the apartment block has decided instead to develop a low-carbon heating system. From what I can see, this is eminently sensible; better insulation is often more costly than simply decarbonising energy supply. The frequent assertion that energy efficiency is always a better route than reducing the carbon content of that energy is simply not backed by the facts in the case of domestic housing.

My first objective when I visited Rostock was to understand how the unit will be used. The first commercial installation – to be completed in the next few months - provides an illustration.

The Augsburg building has a 90 kW PV system on the roof. It contains 70 flats, with an average demand of around 30 kW for the full building. The electricity use will higher in the morning and early evening, and lower at night. There will be periods when PV electricity would spill to the grid. In the Exytron surplus power comes from the roof, it is used to split water into hydrogen and oxygen in an alkaline electrolyser.

2H20 => 2H2 + 02 (+heat)

The oxygen is put into a store while the hydrogen is immediately employed to make methane. CO2 is also in store ready to be streamed with the hydrogen through a Sabatier reactor. The methane that is generated is then stored. The Sabatier reaction gives off heat. This is used for hot water and heating.

4H2 + CO2 => CH4 + 2H20 (+heat)

When the PV system is not generating excess power, the stored methane can be burnt to produce electricity, and heat. In other installations it might be sometimes transferred into the gas grid.

CH4 + 2O2 => CO2 + 2H20 (+ large amounts of heat + electricity)

The two outputs of this part of the process are water and CO2. The water is condensed from steam and used for heating. The CO2 is stored and eventually is piped back to the methanation process where it can be combined with hydrogen. Therefore no CO2 will be produced at any point in the cycle.

In the next installation which will be completed after Augsburg, the whole unit will be contained in three shipping containers in the parking area of the building. The methane, oxygen and CO2 tanks are beneath the ground at another part of the car park. In Augsburg, the units will be contained in the basement.

The round trip efficiency (electricity to electricity) of the Exytron system is about 50%, I was told. However the bulk of the loss is available as useful heat, meaning that the total efficiency is more than 85%, if I understood correctly.

Running the process.

The 90 kW PV installation at the Augsburg building will produce an average of around 10 kW of power over the course of a year. (The panels have to be laid flat, reducing the yield). The average electricity need will be perhaps three times this level. And, of course, the building will require heat as well. So the unit will not just need the electricity from the PV but will also import power to make methane. Dr Busse, the CEO, stresses that there is little benefit to overall CO2 emissions from the process unless renewable electricity is used to make the zero-carbon methane.

Both the local PV electricity and imported renewable power may be stored in a battery. If, for example, spot electricity prices are expected to be low at some later point, it may make sense to store power in advance of need. As I understand the position in Augsburg, the installation is able to buy in electricity at prices that are much lower than the very high German retail tariffs because it will produce low carbon heat.

Surplus energy will be stored as methane. This methane can be burnt at the installation for power and heat/cooling but also can be added to the local gas grid at times of excess.

Dr Busse stressed the difficulty facing operators of local ‘power-to-gas’ systems such as the one in Augsburg. It will need to continuously forecast power and heat needs several days ahead, while also predicting how spot market prices will change as the hours goes by. The system needs to use power when it is cheap and produce it when it is expensive. There will also be occasions when it will be financially better to use standard natural gas to make heat rather than generating it from methanisation from CO2 and hydrogen.

Exytron showed me the numbers that demonstrate that its Augsburg installation will make money for its owners, partly by allowing them not to expensively re-insulate the building and partly because the average price of power is lower when their power to gas system is complete. Exytron told me that the cost of their Augsburg system is about €550,000, or around €8,000 per apartment.

Putting this in a UK context

Imagine a building with a high heat need and also a large renewable energy source, such as PV on the roof. The building buys any extra electricity it needs. These demands will be paid for at different prices at various times of day.

The Exytron system will enable the user to have near zero carbon heat (or cooling) and power. The local PV electricity is used first. When it is in surplus, it is used to generate methane. When it is insufficient the methane is combusted for power and for heat.

At times, such as mid-winter, the PV generated locally will be insufficient to meet daily average demand. Then the Exytron system will buy in electricity when it is cheap – perhaps at night – and make enough methane to cover the power needs of the following day’s peak. When wholesale electricity is very cheap indeed, but the methane store is full, it may even make sense to make gas and export it to the gas grid. (But, as I understand it, this gas would not be zero carbon because the Exytron system would then have to import some natural gas to rebalance its own supplies of CO2).

A user paying 9p (about 11 € cents, 12 $ cents) per kWh for electricity on a standard business tariff may be able to strike a much better deal if it agrees to only buy power between midnight and 6 a.m. The company will certainly not pay the high additional prices for power consumption during winter late afternoons. A closed CO2 cycle plant such as Exytron’s allows a company both to benefit from low night-time prices and use the waste heat from the methanation process. If the company uses only renewable electricity and buys no grid gas, net CO2 emissions are close to zero. However it will probably need to continue to buy some external gas so full decarbonisation may not be achievable.

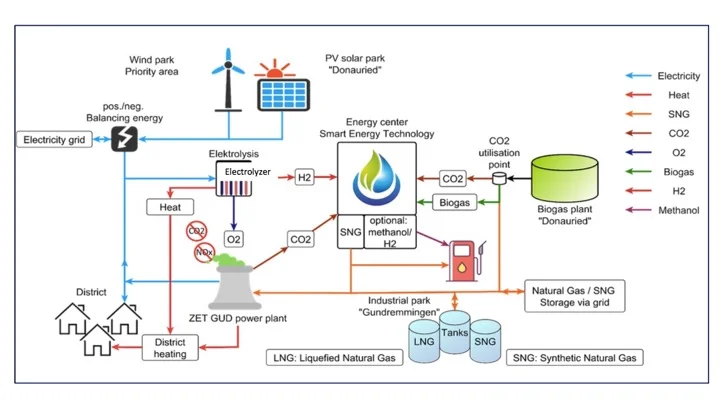

Expanding the Exytron process

The Exytron system is both an electricity storage system and a zero-carbon CHP process. It allows the intelligent shifting of power generation from one time to another and also provides extensive capacity to generate heating and cooling with no CO2. This gives it a potential role in much larger installations than single buildings. Exytron told me, for example, of how its technology might be used to provide both power and heat in the area around one of Germany’s soon-to-close nuclear power stations at Grundremmingen. Waste heat from the power station is currently used for local district heating networks. It would be possible to replace this with heat from the a large Exytron plant(s) powered by new local wind farms, anaerobic digesters and PV sites. It is working with Siemens on this.

It also has an outline of how it might also make methanol (the simplest liquid fuel). Storage of methanol is even simpler than that of methane. The process flow diagram is below.

Costs and the future

At the moment, this is an expensive system. If its first installations are successful, it will get cheaper. It is already possibly the least expensive way to decarbonise heat (heat pumps might be better in some circumstances, using renewable electricity). As electricity continues to get cheaper as a result of falling renewables costs, the relative competitive position of the Exytron system will improve.

Existing power to gas systems, such as Electrochaea’s, require a source of CO2. And they don’t capture the CO2 from the eventual combustion of the methane. Powered by CO2 from anaerobic digesters, they will have equivalent CO2 credentials, but only then. Exytron’s big advantage is that it doesn’t need an independent source of CO2. This means that it can, in theory, expand to cover all the heat, cooling and energy storage needs of the world, whether this in an off-grid Indian village or a major metropolis, provided it can obtain enough zero-CO2 electricity and have big enough gas storage tanks.

Exytron is a plausible contender for a role as the central enabler of the energy transition. But, please note, the company itself doesn’t make this claim. CEO Karl-Hermann Busse, possibly the most pessimistic entrepreneur I have ever met, is far too aware of the obstacles the company faces. He mentions the inertia of many of the existing fossil fuel businesses as important barriers. He says that they will endlessly talk to him but then never commit to partnership. Perhaps a UK company would like an introduction to Dr Busse? No-one should be worried he is going to over-sell his invention.

Having struggled to understand the process logic of the Exytron system myself, I realise that it is complex and in some respects counter-intuitive. However I believe that it is the first genuinely carbon-neutral linked heating and electricity generation system in the world.

[1] Disclosure. I paid for my travel to Rostock. Exytron kindly handled my hotel accommodation and two meals. I am very grateful for the help of Exytron managers Klaus Schirmer and Dr Albrecht Meier and for the extensive gloomy comments of Dr Karl-Hermann Busse, the CEO and inventor.